ThermoVerm vermiculite boards are characterized by a high degree of sound absorption. To prevent reverberation and echo effects, i.e., the reflection of sounds from walls, they can be freely formatted and milled into irregular shapes and surfaces.

Acoustic Panels

- VERMICULITE BOARDS: Acoustic panels

- THERMAL CONDUCTIVITY: λ - 0,16

- TENSILE STRENGTH:COMPRESSION:: 45-58 kg/cm² (PN-EN ISO 8895:2007)

- TENSILE STRENGTH: BENDING: 20-28 kg/cm² (PN-EN 993-7:2001)

- DENSITY: 700 - 900 kg/m³

- LINEAR SHRINKAGE: max. 2% (PN-EN 1094-6:2001P)

- COMBUSTIBILITY: Non-Combustible Material (PN-EN 13501 -1+A1:2009(A1))

- APPLICATION TEMPERATURE: -260 - 1200 °C

The ThermoVerm vermiculite boards are excellent fireplaces insulators. Low thermal conductivity, low weight and fireproof characteristic make them the perfect insulating product. They can be freely formatted, drilled, milled or chamfered according to a drawings or customer requirements. Take care of the heat in your home now.

Fireplace Casings

- THERMAL CONDUCTIVITY: λ - 0,16

- TENSILE STRENGTH: COMPRESSION: 42 kg/cm² (PN-EN ISO 8895:2007)

- TENSILE STRENGTH: BENDING: 16 kg/cm² (PN-EN 993-7:2001)

- DENSITY: 600 - 700 kg/m³

- LINEAR SHRINKAGE: max. 2% (PN-EN 1094-6:2001P)

- COMBUSTIBILITY: Non-Combustible Material (PN-EN 13501 -1+A1:2009(A1))

- APPLICATION TEMPERATURE: -260 - 1200 °C

Vermiculite moulders, insulators, and forms used in fireplaces are produced exclusively from ThermoVerm vermiculite boards, which are characterized by increased mechanical resistance, minimal thermal shrinkage, and very low thermal conductivity. They are responsible for increasing combustion temperature and preventing uncontrolled heat loss. They help maintain a clean glass and reduce fuel consumption.

Fireplace moulders

- VERMICULITE BOARDS: Fireplce moulders

- THERMAL CONDUCTIVITY: λ - 0,12

- TENSILE STRENGTH:COMPRESSION: 42 kg/cm² (PN-EN ISO 8895:2007)

- TENSILE STRENGTH: BENDING: 16 kg/cm² (PN-EN 993-7:2001)

- DENSITY: 500 - 600 kg/m³

- LINEAR SHRINKAGE: max. 2% (PN-EN 1094-6:2001P)

- COMBUSTIBILITY: Non-Combustible Material (PN-EN 13501 -1+A1:2009(A1))

- APPLICATION TEMPERATURE: -260 - 1200 °C

The vermiculite fireproof door panels are manufactured only from ThermoVerm highest quality boards which have a higher mechanical strength, low thermal shrinkage and very low thermal conductivity. According to the regulations, the panels should be installed in the door and elevator door above the 9th floor.

Fireproof Door Panels

- SOUND ABSORPTION 500 HZ: α - 0,4 - 0,6

- THERMAL CONDUCTIVITY: λ - 0,16

- TENSILE STRENGTH: COMPRESSION: 42 kg/cm² (PN-EN ISO 8895:2007)

- TENSILE STRENGTH: BENDING: 16 kg/cm² (PN-EN 993-7:2001)

- DENSITY: 600 - 700 kg/m³

- LINEAR SHRINKAGE: max. 2% (PN-EN 1094-6:2001P)

- COMBUSTIBILITY: Non-Combustible Material (PN-EN 13501 -1+A1:2009(A1))

- APPLICATION TEMPERATURE: -260 - 1200 °C

The vermiculite insulators for heating boilers are manufactured only from the ThermoVerm highest quality boards which have a higher mechanical strength, low thermal shrinkage and very low thermal conductivity. They are responsible for raising the combustion temperature and preventing uncontrolled heat loss

Insulators in heating boilers

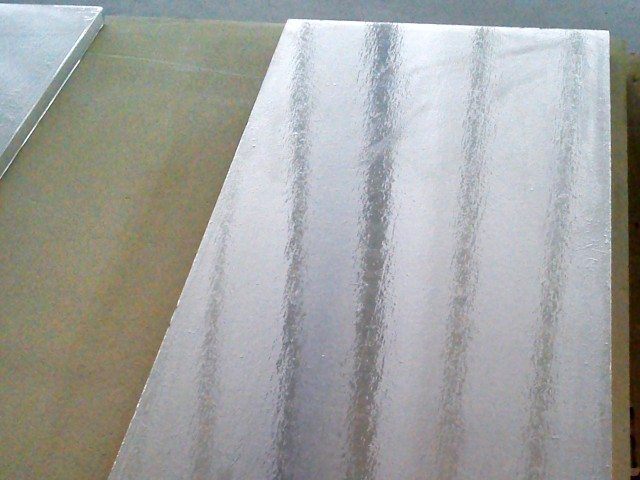

- VERMICULITE BOARD: ThermoVerm - High Mechanical Resistance

- THERMAL CONDUCTIVITY:: λ - 0,09 - 0,18

- TENSILE STRENGTH:COMPRESSION: 40 - 54 kg/cm² (PN-EN ISO 8895:2007)

- TENSILE STRENGTH:BENDING: 12 - 30 kg/cm² (PN-EN 993-7:2001)

- DENSITY: 500 - 1200 kg/m³

- LINEAR SHRINKAGE: max. 2% (PN-EN 1094-6:2001P)

- COMBUSTIBILITY: Non-Combustible Material (PN-EN 13501 -1+A1:2009(A1))

- APPLICATION TEMPERATURE: -260 - 1200 °C

We are the direct manufacturer of the ThermoVerm vermiculite boards. By using of a modern technology We make the high quality product – the boards retain their structure, don’ t crumble and crack. They could be cutting to smaller insulation moulders. If You have any problems with a standard vermiculite boards, We have the solution!

Vermiculite Boards

- VERMICULITE BOARDS: Boiler Insulators

- THERMAL CONDUCTIVITY: λ - 0,14

- TENSILE STRENGTH: COMPRESSION: 42 kg/cm² (PN-EN ISO 8895:2007)

- TENSILE STRENGTH: BENDING: 16 kg/cm² (PN-EN 993-7:2001)

- DENSITY: 600 kg/m³

- LINEAR SHRINKAGE: max. 2% (PN-EN 1094-6:2001P)

- COMBUSTIBILITY: Materiał niepalny (PN-EN 13501 -1+A1:2009(A1))

- APPLICATION TEMPERATURE: -260 - 1200 °C